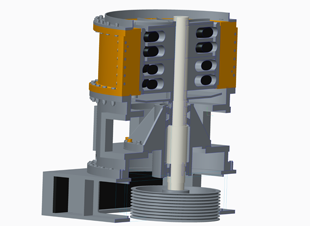

HGM Series Three-rings (Four-rings) Micro-Powder Grinder Mill is a new type of high efficient fine powder and ultrafine powder processing equipment.

Limestone

Basalt

Granite

Pebbles

Construction

Power

Dry Mix

Chemica

Building

Mining

HGM Series Three-rings (Four-rings) Micro-Powder Grinder Mill is a new type of high efficient fine powder and ultrafine powder processing equipment, which is by our technology research and development center through introducing advanced foreign technology and develops for years of concentrated innovation research and design transformation. This type grinding mill is mainly suitable for grinding nonflammable and non-explosive brittle materials with low and middle hardness (mohs hardness < 6) and moisture content less than 5%.

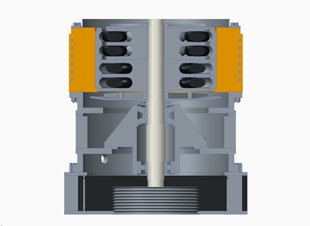

The equipment adopts the innovative comminution structure of multi-layer and multi grinding channel.

Forged by special material, the ring and roller can be used for about one year while grinding calcium carbonate.

The damping spring and sealing belt can reduce the vibration and noise and avoid the resonance between mill and classifier.

Compared with jet mill, mixing grinder and ball mill of same finished product size,HGM Micro-Powder Mill has double capacity and saves energy.

Model | HGM80 | HGM100 | HGM125 | HGM168 | |

No.of Roller and Ring | No.of Roller (Pcs) | 21 | 28 | 32-36 | 40-44 |

No.ofRing (Pcs) | 3 | 4 | 4 | 4 | |

Input | The Feeding Size(mm) | ≤20 | |||

Capacity(Kg/h) | 500-5000 | 1000-8500 | 1500-12000 | 5000-25000 | |

The Final Size | Micron | 45-3 | |||

Mesh | 3250-325 | ||||

Motor Power (KW) | Main Mill | 55-75 | 132-150 | 185-220 | 315 |

Classifier | 18.5 | 37 | 55 | 18.5x5 | |

Air Blower | 45 | 75 | 132 | 160 | |

Screw Conveyer | 2.2 | 2.2 | 3 | 4 | |

Discharge Valve | 2x0.75 | 1.1 | 1.5 | 2/1.5 | |

Air Compressor | 7.5 | 15 | 22 | 30 | |

Overall Dimension (Length x Width x Height)(M) | 13.9x4x6.2 | 18x4.6x8.6 | 14x9 x 10.25 | 26.3x7.5x11.9 | |