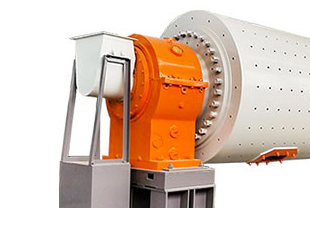

Ball mill is key equipment for the secondary grinding after the primary crushing. The material enters the first warehouse of the mill evenly from the hollow shaft by the feeding device.

Limestone

Basalt

Granite

Pebbles

Construction

Power

Dry Mix

Chemica

Building

Mining

Ball mill is key equipment for the secondary grinding after the primary crushing. The material enters the first warehouse of the mill evenly from the hollow shaft by the feeding device. The warehouse is equipped with a ladder liner or corrugated liner, different specifications of the ball, and the cylinder rotating centrifugal force to bring the steel ball to a certain height after the fall and it has a heavy blow and grinding effect to the material.With rough grinding after in the first warehouse, the material with the secondary grinding in the second warehouse and which has a built-in liner and then it discharged by the discharge grate plate.

The design of discharge is flexible and discharge port is reasonable, can choose iron remover according to needs.

The feeding volume of the feeding part is large, and the reasonable design of the feeding port increases the feeding volume.

It adopts the unique small gear to drive the big gear, which makes the operation more stable.

The closed system is adopted to reduce the dust. The closed system is formed by the ultra-fine ball mill and the classifier.

Model | Rotary Speed(r/min) | Ball Weight(t) | Feeding Size(mm) | Output Size(mm) | Capacity(t/h) | Power(kw) | Weight (t) |

φ900x3000 | 35.6 | 2.4 | ≤25 | 0.075-0.89 | 0.8-2.5 | 22 | 5.3 |

φ1200x3000 | 32.4 | 4.5 | ≤25 | 0.074-0.4 | 1.6-3 | 37 | 12.1 |

φ1200x4500 | 32.4 | 7 | ≤25 | 0.074-0.4 | 1.83-3.9 | 55 | 13.1 |

φ1500x3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2.8-4 | 75 | 14.8 |

φ1500x4500 | 29.7 | 11 | ≤25 | 0.074-0.4 | 4.8-7 | 110 | 19.9 |

φ1500x5700 | 29.7 | 14 | ≤25 | 0.074-0.4 | 5-8 | 130 | 23.4 |

φ1500x7000 | 29.7 | 17 | ≤25 | 0.074-0.4 | 6-8 | 155 | 27.5 |

φ1830x3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4.5-10.5 | 130 | 26.6 |

φ1830x4500 | 25.4 | 17 | ≤25 | 0.074-0.4 | 6.8-11.5 | 155 | 30.4 |

φ1830x6400 | 25.4 | 24 | ≤25 | 0.074-0.4 | 7-12 | 210 | 32.3 |

φ1830x7000 | 25.4 | 26 | ≤25 | 0.074-0.4 | 7.8-13.8 | 245 | 34.2 |

φ2100x3000 | 24.9 | 15 | ≤25 | 0.074-0.4 | 5.8-14 | 210 | 32.3 |

φ2100x4500 | 24.9 | 23 | ≤25 | 0.074-0.4 | 9.5-18 | 245 | 40 |

φ2400x3000 | 20.8 | 20 | ≤25 | 0.074-0.4 | 7.8-18 | 245 | 51.3 |

φ2400x4500 | 20.8 | 30 | ≤25 | 0.074-0.4 | 13.7-28 | 380 | 63.7 |

φ2700x4000 | 19.5 | 34 | ≤25 | 0.074-0.4 | 15-28 | 475 | 89 |

φ2700x4500 | 19.5 | 39 | ≤25 | 0.074-0.4 | 16.5-36 | 475 | 97 |