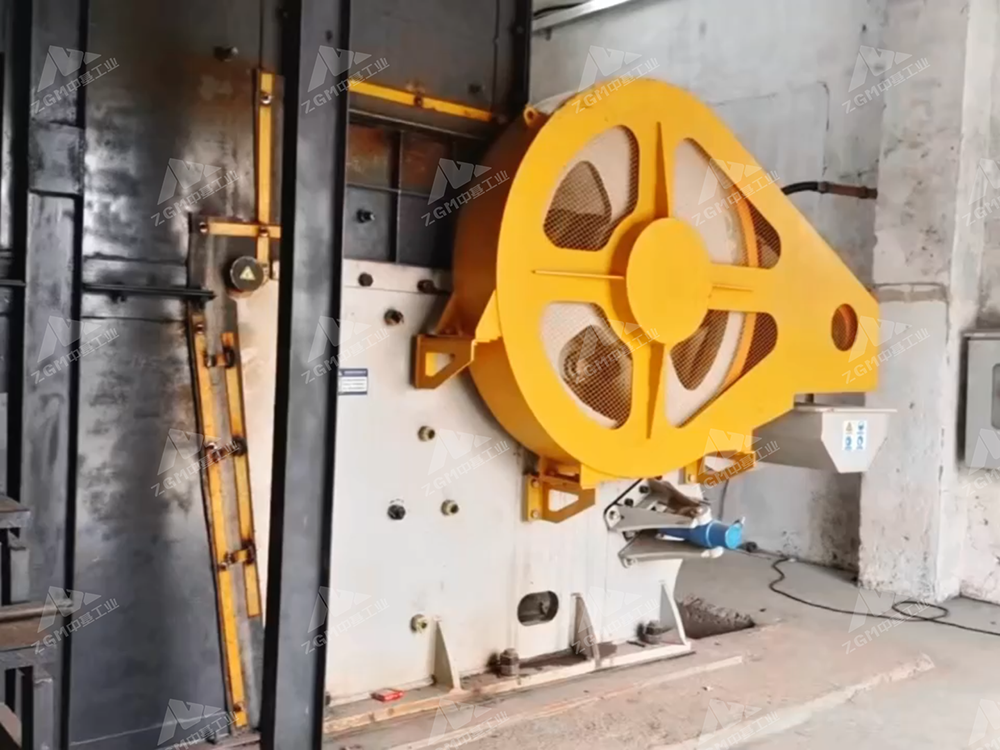

Recently, at a customer project site of Henan ZGM Industrial Technology Co., Ltd., a scene of bustling activity unfolded—a meticulously designed and robust steel structure hard rock crushing production line was being installed in a well-organized manner. Every detail, from equipment commissioning to production line layout, showcased ZGM Industrial's craftsmanship and underscored the company's deep expertise in the mining machinery sector.

Henan ZGM Industrial Technology Co., Ltd. is a globally renowned industrial production technology enterprise. Since its inception, the company has focused on the R&D and manufacturing of high-end, efficient, and environmentally friendly mining equipment. Integrating scientific research, production, sales, and service, ZGM Industrial boasts modern standard workshops, large-scale CNC machining centers, and other advanced production facilities. With its reliable product quality and comprehensive after-sales service system, the company has earned widespread market recognition, with its products sold domestically and internationally, establishing a strong reputation in the industry.

This is a typical steel structure hard rock crushing production line, featuring a core equipment combination of an "E-type jaw crusher + single-cylinder cone crusher + vibrating screen." Compared to traditional concrete foundation production lines, the steel structure line offers significant advantages, including a shorter construction period, lower foundation requirements, strong site adaptability, and ease of relocation. These features make it particularly suitable for projects with tight deadlines and complex site conditions.

The E-type jaw crusher delivers powerful crushing force and a sturdy structure. Its symmetrical "V"-shaped chamber design enables efficient processing of large, hard rocks, providing ideal feed size for subsequent crushing stages. The core components are highly stable and durable, withstanding the impact of hard ores. The hydraulic wedge block discharge adjustment system ensures high automation in maintenance, and the modular design facilitates easy disassembly and transportation.

The single-cylinder cone crusher employs advanced single-cylinder hydraulic technology, integrating mechanical, hydraulic, electrical, and intelligent control systems. It not only offers high crushing efficiency and large processing capacity but also allows for precise control of discharge size through the hydraulic system, ensuring cubic-shaped final products without tension cracks—ideal for high-grade concrete raw materials. Its excellent iron passage protection and stable laminated crushing principle ensure high reliability and long service life when processing hard rocks, making it an ideal choice for producing high-quality aggregates.

The vibrating screen features a cylinder-type eccentric shaft exciter, with adjustable amplitude via counterweights. Its multi-layer screen design prevents clogging, ensuring high screening efficiency, low noise, precise grading, and large processing capacity. This guarantees the cleanliness and grading accuracy of the final product, meeting customized needs for various application scenarios by producing multiple specifications of finished materials.

Advantages of the Steel Structure Production Line

Modular Design: All levels of equipment and transfer corridors use modular steel structures, significantly shortening construction time.

Sturdy & Durable: Main beams and support structures are made of heavy-duty H-beams and plates, capable of withstanding long-term operational impacts and vibrations.

Compact Layout: A scientifically optimized process layout minimizes the production line's footprint and maximizes space utilization.

Intelligent & Eco-Friendly: The centralized electrical control system offers high automation, user-friendly operation, and low running costs.

This type of steel structure hard rock crushing production line is widely used in the crushing and processing of medium-to-high hardness materials such as granite, basalt, river pebbles, and diabase. It serves as a core production facility for high-quality sand and stone aggregates required in construction, highways, railways, water conservancy, and hydropower. Once successfully installed and operational, the line will provide customers with stable, high-yield returns, serving as a robust tool and "money tree" for market expansion.

From order signing to manufacturing, equipment delivery to on-site installation, ZGM Industrial offers full-chain service capabilities, delivering high-quality mining machinery solutions to global clients. Moving forward, the company will adhere to the principles of "steady operation, continuous innovation, and open cooperation," driving technological advancements to provide customers with more advanced, efficient, and environmentally friendly integrated crushing solutions. Together with industry partners, ZGM Industrial will create a brilliant future!